OUR TECHNOLOGY

Innovative technology for the manufacture of nanostructured silicon anodes for lithium-ion batteries

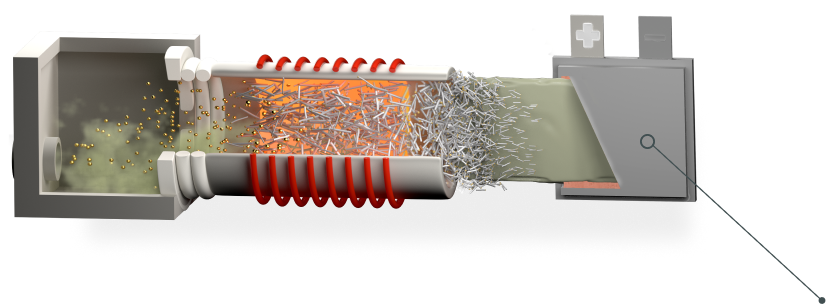

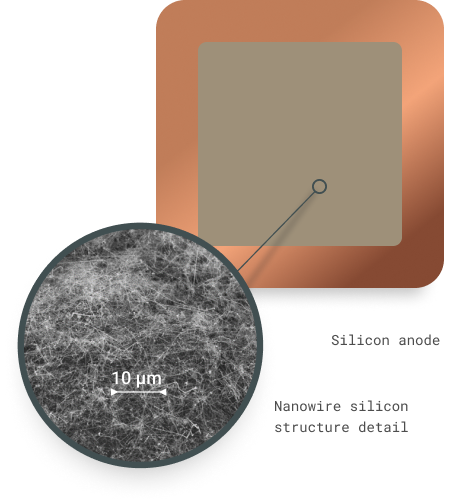

Floatech’s process has emerged from a new branch of chemical vapour deposition (CVD) research that utilizes floating catalyst nanoparticles for enhancing traditional CVD processes. In this, a gaseous Si source is directly converted into a free-standing SiNW sheet, a semi-finished electrode, in one single process. In addition, due to the ultra-long length of the constituent nanowires, the semi-finished electrodes are mechanically robust and do not require reinforcing binders. Hence, costly dispersions of raw materials and the use of substrates are eliminated. Our SiNW sheets can be directly deposited on current collector foil for integration into LIBs as full anodes.

Floatech’s single step manufacturing process

Our process transforms a silicon gas into a semi-finished electrode in a single step. This process eliminates the need to produce dispersions of raw materials and deposition on substrates. Thus, costly processing solvents from electrode manufacturing become obsolete.

THE RESULTS

Our silicon nanowire (SiNW) sheets can be easily integrated into LIBs as high capacity anodes and withstand extreme volume changes during lithium uptake.

- One-step manufacturing process that eliminates solvents, polymers and binders, reducing costs and emissions.

- Increase the efficiency and lifespan of lithium-ion batteries.

- Mechanically flexible and robust electrodes.